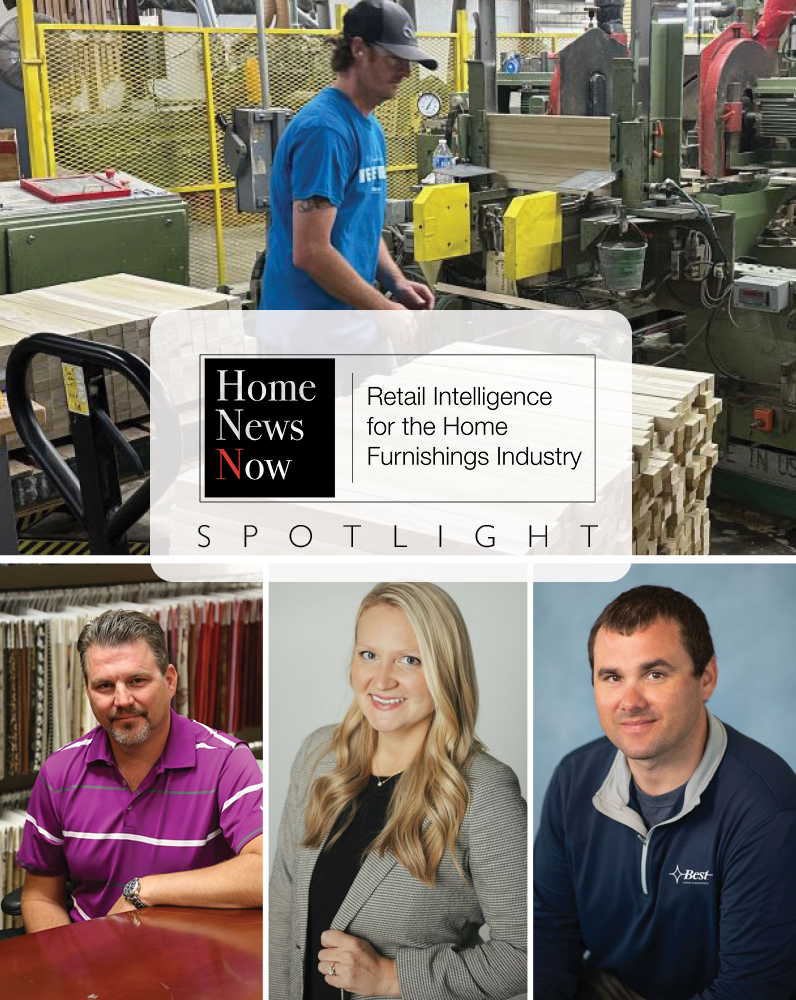

Originally published by Home News Now, 7.23.2024 | Thomas Russel:

Company also looks to grow with a new generation of family management and skilled manufacturing talent.

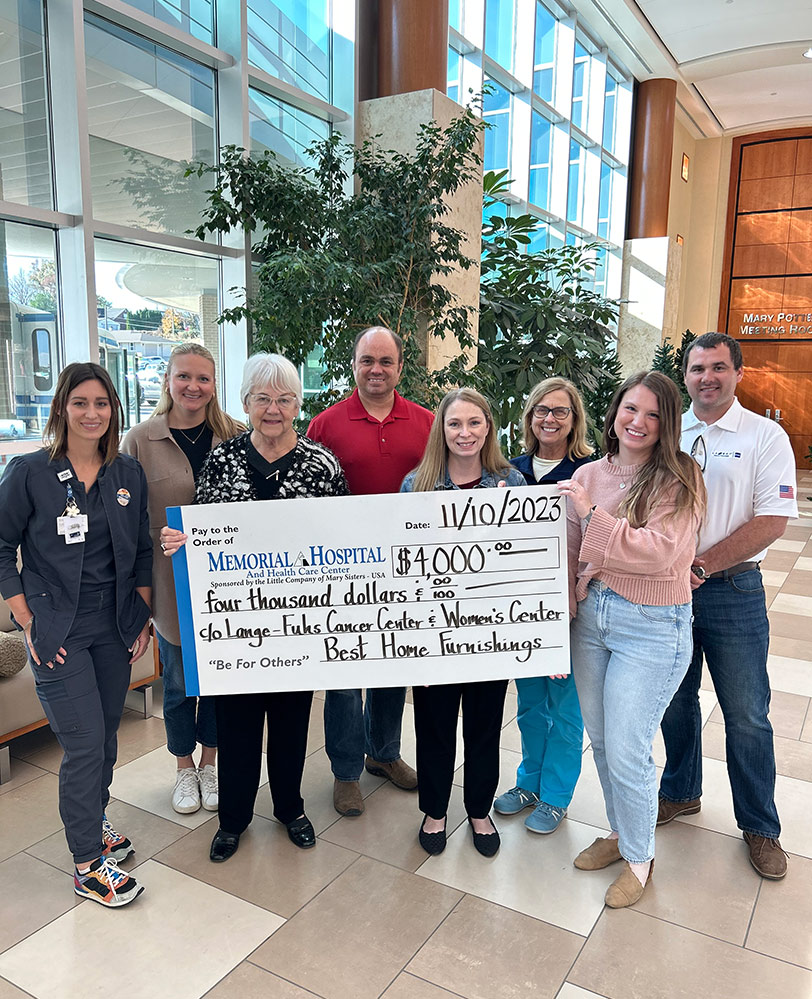

FERDINAND, Ind. — With more than 60 years of upholstery manufacturing experience to its credit, Best Home Furnishings is poised to take its business to the next level, with new products, new designs and a new generation of young family leadership coming up the ranks.

Started in 1962, the third-generation business continues the legacy of founders Clem and Mary Lange and Ernie Prechtel Sr. who started the company as an upholstered chair manufacturer. Hence for years, the company would be known as Best Chairs, highlighting a seating category that would eventually grow to include glider rockers and recliners as well as sofas, loveseats, sectionals, dining chairs, bar stools and much more.

Yet as the line grew, the company remained steadfast in its dedication to a U.S. manufacturing model. Today, it produces its entire line in more than 1.1 million square feet, spread over several buildings in and around Ferdinand that employ around 725 workers, just shy of 1000 at its peak from around 2010-12 . At roughly eight to nine days, lead times are among the most competitive in the industry for special order products, although officials would like to lower that even further to about five or six days as business improves.

It is in this manufacturing environment that many second- and third-generation family members have learned the business from the ground up, from the way a seating frame is constructed to how to apply multiple layers of padding and fabric to the frame.

“It is what drives it,” said President Brian Lange, one of four children of founders Clem and Mary Lange and the father of Lydia Lange and Janae Lange-Wendholt, the company’s vice president of design and development and a member of the executive committee. “I’ve always told my daughter that if you can build it, you can sell it. That’s why going into research and development she literally had to build furniture.”

Lange said that Janae’s designs have brought a more updated transitional aesthetic to the line that will appeal to female consumers. In fact, he noted, one of the swivel chairs she designed was the company’s No. 1 seller for some time.

Lange said that while he and Janae don’t always agree on matters, “we talk it out and try to figure out what’s best.” He also noted that while he typically has the ultimate say-so on various decisions, he still encourages his team to consult with Janae throughout the process.

“It think it’s important because, otherwise, I’m the one that’s making all the decisions,” he said. “When I get management coming in here wanting to ask me a question, I right away say, ‘Did you talk to Janae?'”

Several other third-generation family members are also involved in the business, including Lange’s nephew Tyler Wendholt, the son of Brian Lange’s sister, Sheila Wendholt. He is vice president of design and development at sister health-care division Knú and director of operations of Jasper Dimensions which produces upholstery frames for both Knú and Best.

And like Janae, he also is a member of the company’s executive committee as are three other grandchildren of Clem and Mary, including Brad Wendholt, also customer service return manager and the son of Brian Lange’s sister Sheila; Alexa (Lange) Gasser, administrative support manager; and Tori (Lange) Thimling, social media manager.

“Nobody is above manufacturing in a sense,” added Senior Marketing Strategist Eric Vollmer, who first joined the company in December 2002 and later married Lacey Wendholt Vollmer, the daughter of Brian’s sister Sheila. Today, after nearly 22 years with the company, he remains a key part of the family business and has observed how other family members have grown into their respective roles through their first-hand experience, whether in the production or purchasing offices or out in the plant.

“The whole dynamic of the family works really well,” Vollmer said. “Everybody respects each other’s roles and understands how the puzzle fits together. And obviously, the third generation respects very much what their parents did and what their grandfather did.”

That includes a keen awareness and understanding of the company’s long-time domestic manufacturing model.

“So they all started out doing some kind of manufacturing job during college and during the summers,” Vollmer added. “I think everyone that is involved now did that in order to understand that aspect of it. That is kind of where it all starts and how we’re able to do what we do.”

The recruitment of talent across age and experience levels is also important for the company’s production facilities where jobs range from frame building and other wood processing to the cutting of foam, fabric and leather, not to mention the application of those materials to various frames.

With unemployment hovering just over 2.5% this past spring in Ferdinand and surrounding Dubois County, it’s been a challenge to find good help in almost any circumstance.

“It is starting to loosen up a little bit, but there for a while, you couldn’t hire anybody,” said Brian Lange, noting that for years, many thought they had to attend college to get a decent paying job. “Now things are starting to change and you might be better off going into the workforce. And you know, the pay is substantial now.”

Without revealing specifics about employee compensation, he noted that the average pay at Best has risen 35% to 40% in some areas since 2019.

Such increases also help the company remain competitive with other employers in an area that’s home to other furniture and cabinetry producers such as MasterBrand Cabinets, office furniture producer Kimball International, CNC equipment manufacturer Thermwood Corp. and Jasper Chair Co., to name several.

Yet as many of Best’s factory jobs — with the exception of engineers — don’t require an advanced degree, the company is engaged with local high schools where there are training programs in place that allow students to build a piece of upholstery from the ground up with a wide mix of components and other materials.

“We have three schools with industrial arts classes, where we are bringing in components and teaching them how to build a piece of furniture,” Lange said.

Regardless of whether its next generation of workers need a degree or not, their skills will be important for a company that continues to innovate its line in areas such as lift chairs, zero gravity chairs, massage chairs and other motion furniture, much of which offers health benefits for consumers of all ages.

About half its line has some type of motion or reclining capability, officials estimated, noting that the company abandoned its once popular wooden gliders over the past year or so. Demand in that segment dried up as more and more consumers — namely young moms in their 20s to mid-30s — sought the comfort and functionality of upholstered recliners and upholstered swivel gliders for example.

“We’ve been doing lifts for a long time and with the amount of resources we’ve invested in this kind of program, there’s nobody that can touch our selection and the offering that we have with lifts right now,” Vollmer said.

Of the decision to abandon wood gliders, Lange noted, “A few people in the Midwest were kind of disappointed we were getting out of it,” he said. “But the volume just wasn’t there. … Even while we were in it and everybody else was getting out of it, our business still didn’t increase. So you know that it is kind of a dying market.”

The company does roughly another 35% of its business in accent chairs with the balance in stationary, which has been in the line since around 2005. Calling it a still fairly new category, officials believe stationary will continue to be a major growth area, although the company is looking for growth in all segments, particularly as it adds more features, including higher grade leathers to its lineup to differentiate itself from less expensive imports. In that respect, it hopes to fill a void in the marketplace, Lange noted, adding that the company will continue to offer starting to mid-price points as part of a good, better, best offering within the full product line.

Stationary fabric and leather sofas retail around $1,299, while manual fabric and leather recliners retail from $599 to $749 respectively and power fabric and leather recliners retail from $749 to $849 respectively. Manual fabric and power reclining sofas retail from $1,149 to $1,349, while leather versions with manual and power reclining functionality retail from $1,499 to $1,699.

“We want to revamp our whole strategy when it comes to leather,” Lange said, noting that there are about 35 leathers currently compared with about 750 fabric options. “The funny thing about leather is that you’ve got high end and you’ve got low end, and there’s nobody in between.”

Here, too, the vertical nature of the operation ranging from the production of frames to the cutting of foam, fabrics and leather on-site, helps control both quality and speed to market. Part of the company’s DNA as a domestic producer, these in-house capabilities also are a key part of its strategy to achieve continuous improvements that not only support its manufacturing operations, but that also provide the best quality and custom options for its customers.

“Our strategy has been to do custom orders and deliver it fast,” Lange noted. “That was our strategy to compete with imports. And that model has stuck and we’ve done very well with that model. We can put 750 different fabrics on a chair and our customers seem to like that. Our retailers also can make more money on a custom order. There are some out there that don’t know how to handle a custom order, but the ones that do, do very well with it.”

To read the whole article with additional pictures and information, please click here.

Favorites

Favorites